How to Repair Metal Earth Models: The Missing Manual

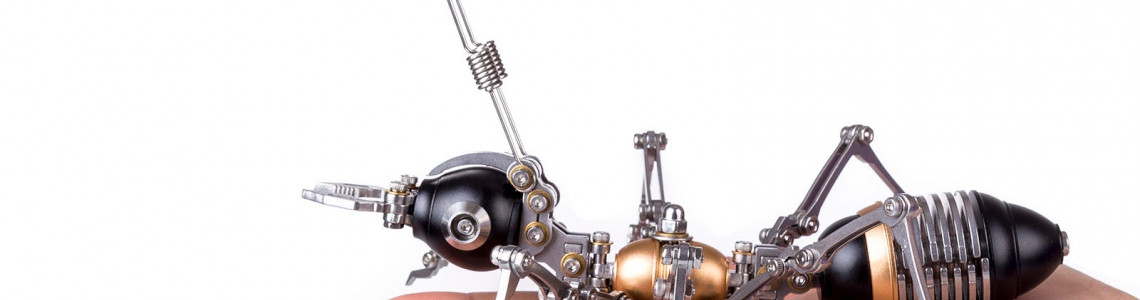

How to Repair Metal Earth Models: The Missing Manual

I've been creating 3D laser-cut metal models for a few years now, and fortunately, as I've gained more skill, I've seen fewer of those annoying "mishaps." However, I still occasionally break a piece, generally along a fold line. Sometimes, even the most skilled builder must know how to fix metal earth models. Later, when the models are on display, they may even break.

How can Metal Earth models be fixed? Super glue, or cyanoacrylate, is the most often used repair technique. When reassembling two metal pieces, a thin layer of adhesive is necessary to hold them together without gaps for a longer period of time.

That's the quick response. There's more to say about that, and I hope you'll find some further recommendations helpful.

First of all...

Using Super Glue to Repair Metal Earth Models

For most modellers, this is the "go-to" approach.

However, it's not as simple as picking up a tube and squeezing it. Knowing a little about super glues—or cyanoacrylates, to use their scientific name—will help you utilize them correctly.

The family of strong, usually highly fast-acting adhesives known as cyanoacrylates are used in industry, medicine, and the home. Metal Earth modellers must be aware of these most crucial things.

The shelf life of superglue is short. They might only survive a year or so after manufacture, even if you never open the bottle or tube. That life can decrease to as little as one month once the container is opened. A tube can last much longer than that, in my experience, but it's not unusual to reach for your glue and find it useless. The advice is to avoid buying it in bulk and to be ready to purchase a new tube frequently (thankfully, it's inexpensive). Additionally, you can prolong its useful life by keeping it in an airtight container with a silica gel desiccant package.

It is best to use it sparingly. Regular humidity levels impact the chemical reactions that lead to the quick setting of cyanoacrylates. They slow down the responses, causing thin skin to form in seconds. "I want a strong bond, and I want it to 'grab' quickly, so I'll apply more glue," is a common thought. This is the exact opposite of what should be done. It accomplishes the opposite goal. More applications will usually result in a slower setting time and less strength.

Hold the metal parts you are bonding in place for a more extended period. Different materials react differently to cyanoacrylates. They will instantly bond specific polymers. However, it is nearly impossible to connect glass correctly. When attaching metal to metal, you will need to hold the parts together for a little longer than you would for other materials. Don't expect the bond to form quickly. Although the first bond usually forms within a full minute, it is preferable to put your model aside and allow the glue to dry for a while, preferably overnight.

Keep gaps to a minimum. The process functions best when there are no gaps between the metal surfaces. However, any gap can affect the strength of your final bond.

Pitfalls to Avoid When Using Super Glue

Prints of glue. If you position your fingers incorrectly and apply the glue while it is curing, you might discover an unsightly fingerprint on the surface of your model that you will never be able to get rid of.

Affixing glue to your fingers. Since most of us have done this at some point, using an applicator is ideal (a paper clip is a great tool). If super glue does cause your skin to become bound, the most straightforward approach to soften it is to soak in or swab it with warm, soapy water. It can also be beneficial to add vinegar to the mixture.

Toxicity. Because cyanoacrylates are poisonous, you should not inhale their vapours. Therefore, use it only in an area with adequate ventilation.

Which One to Buy?

Zap-a-gap Medium CA+ is the brand of superglue I favour. It works well, is simple to use, and appears to have a slightly longer shelf life than others. Additionally, Zap-a-Gap manufactures Zip-Kicker, a superb matching "activator" in a spray can. Applying the glue accelerates the curing time by simply spraying a very brief burst of the activator. This is particularly useful when it comes to metal on metal.

Loctite is another brand that metal modellers favour. This is the original superglue brand. Many people adore that it now features squeeze buttons on the tube's side for greater control.

Additionally, certain brands are "UV activated." Some are packaged with a tiny UV flashlight. This functions as an additional type of activator. Check out Bondic, 5-Second Fix, or Laser Bond if you'd want to try this kind.

Try Aluminum Tape to Repair Metal Models

Though it has few uses, this is an additional concept to consider. Taping can be used if the break is to a part that won't be seen on the finished model because it's internal or will be obscured by surrounding parts. A Metal Earth model and aluminium tape are nearly the same hue.

Need Another Solution?

Never try to reattach a tab that has snapped off. First, they are typically very small, making it extremely difficult to execute. Additionally, following repair, you will need to bend the tab once more, increasing the likelihood that it will break again. The two pieces that the tab would have held together are better off just being glued together.

If everything else fails... Fascinations Inc., the Metal Earth firm, has established a stellar reputation for customer service. Additionally, modellers frequently mention that after contacting the company via email for assistance, they promptly received a replacement sheet at no additional cost. It's better than throwing out a model kit if you're truly stuck, but we don't want to bombard them with requests like this. Naturally, we are unable to attest to comparable service from other brands.

Preventing Breaks in the First Place

A fold can only be bent roughly twice. Anticipate that it will break after that. So, before you continue, ensure you're folding the right way at the right moment.

Go ahead and read the directions. This is an essential advice. Although the instructions are generally good, there are instances where the sequence they specify makes construction extremely difficult, if not impossible. For instance... The F4U Corsair from Metal Earth has an "easy" rating. It's practically impossible to construct if you adhere to the directions strictly! In step 1, you are instructed to close the tab and bend the fuselage into form. However, the following steps instruct you to attach other sections with tabs that must be locked inside the fuselage, which is now closed. By reading ahead, you can anticipate this and postpone shutting the fuselage in step 1.

Look up a build report online before you start building. Enter the model's name to check if anyone has shared their experience creating it. It might be a YouTube video or a blog piece. They can warn you about potential construction-related issues.

Although there aren't many build reports, our hobby is expanding rapidly. Therefore, this will change in the coming years.

A Final Word

This has been a handy resource for fixing Metal Earth models. (I genuinely hope that doesn't happen too frequently!)

However, I understand. Breakdowns can be very annoying. That partially built Metal Earth model may make you want never to repurchase another one.

I want to urge you not to. Keep trying. After resting, think about your options again.

These issues should decrease as you create more 3D metal models. You will learn to break parts less frequently. However, I can guarantee that even highly skilled modellers occasionally make mistakes.