Build: Monster Truck

Build: Monster Truck

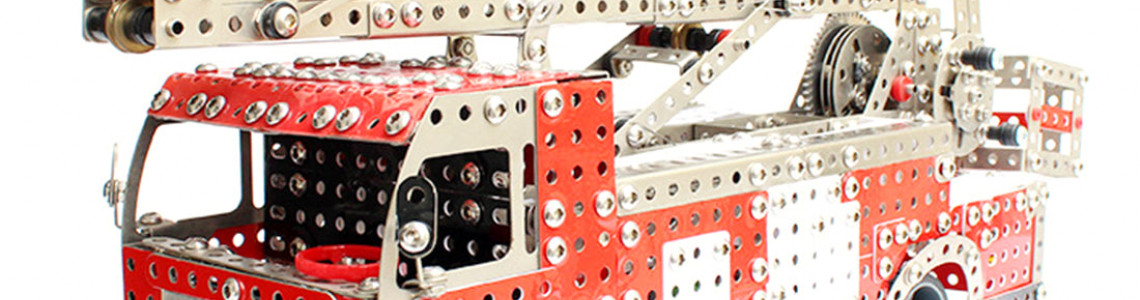

Some builds are successful. Not all builds do. One of the latter was the Monster Truck I built. The outcome came out very good, however I am solely responsible for the aspects that didn't work out. And before I started the project, what was the one issue that frightened me the most? Yes, it's the most attractive aspect! In any case, this is my tribute to the reality that everyone makes mistakes occasionally. Additionally, I exploit that truth because I'm often better at hiding the consequences and getting over them.

Before I explain how I made many mistakes, let me just say that I think this model looks excellent and has some really awesome details. Take a look at this thing's tiered suspension! Additionally, those tires' treads are really harsh. It's entertaining, striking, and appears to be serious. Additionally, it's rather large for a Metal3dpuzzles model of the classic size.

Now for the exciting part. You ask, how did I make a mistake? I was primarily responsible for it. And the reason for that was that I did some things that I knew were wrong. Things I advise novice builders to avoid. I didn't follow the directions very carefully. And without consulting the directions, I assumed how things would proceed.

Additionally, I didn't use the 360 when the directions weren't clear. Regretfully, not all simultaneously. This led to two really annoying issues at the conclusion of the build, as well as one error that is still there and that I haven't rectified since I simply can't, but perhaps another day.

Prior to all of that, though, I struggled because of my large, foolish fingers. You see, those incredibly intricate suspension and undercarriage are where the build begins. Additionally, although it is fantastic, complicated, and multi-layered, it is also sensitive and fragile (it's easy to get all worked up over it). If you insist on folding tabs instead of twisting them, it can also be a nightmare of balancing acts (again, that's on me). Furthermore, those items are incompatible with someone whose fingers are like sausages. Let's go on to the individual call-outs, though!

I made a few different deviations from the directions when I started the undercarriage project. Initial of all, even though the labeling in the directions indicates that the Engraved side should be up, I made component 5, the initial portion, with the Not-Engraved side up (though the shading seems to be consistent with the way I approached it). I made this decision because I didn't believe any of the engravings were merely decorative, and using the etched line on the "outside" of the fold makes folding easier. In a similar vein, even though the instructions suggested otherwise, I approached section 6 in the same manner. After rolling them flat side out on part 7, I fastened them to part 6 before fastening part 6 to part 5. There was enough space to fit the tab-laden ends of parts 5 through 7 into the slots of part 6, so I switched up the sequence because I prefer not to form cones around existing parts wherever possible. Oh, and the long strips on the exterior of part 5 that have tabs on the ends. In part 6, I didn't smooth out the ends of the folded-over flaps. When securing them, I left them inclined into the slots so as not to twist the metal.

I became somewhat perplexed by some uncertainty when you reached the section where you are meant to form the undercarriage's sides, and I neglected to verify the 360 as I should have. Thus, this aspect of my build is still incorrect as of right now. The horizontal bars at the bottom of each side flex differently on the two sides, as you can see. In the second part of that step on Part 11, they bend slightly upward, and in Part 14, they bend a little downward. I assumed incorrectly that the first one was true and that both of them should have a tiny upward bent. Actually, the reverse is true.

Furthermore, the diagram indicates that there is a cut in the vertical portion of these bars next to the point where they connect to the entire assembly. It's challenging to get that curve in there because there isn't this cut. However, I made the most significant headache by bending them in the wrong direction because I had to keep trying to straighten them out laterally throughout the remainder of the project.

It's weird to attach those sides to the rest of the undercarriage, particularly if you unintentionally fasten one of the tabs to the incorrect slot. I didn't do it. I didn't do that at all. Furthermore, I immediately realized that I had distorted the remainder of the undercarriage in order to align the central tab. In addition, I'm lying to you at the moment. However, getting everything in line is still a little challenging.

Additionally, the final product is not particularly robust once everything is attached. Since there is currently nothing to create solid right angles, it bounces around. I wish I had gone ahead and fastened the cab interior to the top tabs right here, then returned to secure parts 15 and the subassemblies for parts 9 and 10. Because it's entertaining to attempt to keep everything together while aligning all the tabs and slots for those. Naturally, I didn't do that, so I don't know if that strategy would have any disadvantages of its own.

Forming the smaller of the wheels' internal cylinders is another area—albeit a very modest one—where I deviate from the directions. It states that the tabs in part 16 that go through part 17 can be twisted. And I'm not really sure, but you might be able to accomplish that. But because the two inner cylinders of the wheels come extremely close together once the wheel halves are linked together, I have previously been bitten by colliding twisted tabs when I followed that approach when creating comparable wheels. Therefore, just to be cautious, I suggest folding these tabs.

The next thing I want to draw attention to is the steps where you perform the model's most noticeable feature, which is the highly ready tires and wheels. These actions are time-consuming. They are also repetitious. And boring. Additionally, the instructions omit a characteristic that consumes a significant amount of your time throughout these steps: curved tread sides after folding down. The treads are a little bent. And they consider this while attaching the side flaps. However, you must curve the ends on one side of each tread and the midsection in on the other after folding those flaps over. The labor is tedious and meticulous. Although it does produce a cool-looking effect, I would have preferred it if they had added a slight bend along the treads' "vertical" plane to prevent them from protruding or moving away from the tire surface in the center. But I'm simply finding faults.

Speaking of the treads' final placement, I was terrified of that aspect of the construction. That would be the most annoying thing. Because I frequently had the Farm Tractor model's tires' treads colliding and obstructing one another. The prospect of four enormous tires' worth of treads did not excite me. However, this time, it was much simpler (at least for me). The sole reason for this is that the treads fold down and rest on the tire at an angle rather than perpendicular to the sidewalls. You may push the treads to the side to flatten them out and then bring them back to the center, thanks to that angle. Unfortunately, I know someone who apparently struggled a lot in this region since they were unaware that the treads were set down at an angle.

That's not to suggest it was simple, of course. Said it was more straightforward than the tractor's treads. To help some of this process go more smoothly, I'll give you some tips. I discovered some tips along the way. Before you start, check the tread pattern on the tire's cylinder again. When you start folding down the treads on one tire, it's terrible to discover that you put that on backward. I know that. Furthermore, before you attach it, I recommend beginning the bends on the tire half that is connected to the rest of the model. Since there may be some tight spaces while working with the treads next to the rest of the model's framework, this makes things easier.

When you finally start folding over the treads, choose a starting point and align the two opposing or adjacent treads with the tire's cylindrical base pattern by folding them to the middle. Next, go "away" from the "direction" that the two treads are pointing by alternatingly folding down the treads from both sides. Going with the treads was my first inclination; however, when all the treads around that location are still sticking up, it can be challenging to line the treads you're pressing down. Moving oppositely gives you more elbow room (or, perhaps more accurately, knuckle room).

When we finally reached the section of the instructions where I failed to pay attention, I assumed how items would be attached. In close vicinity, yet not precisely at the exact moment. And it all comes down to constructing and affixing the monster truck's body. The sides were the first of the two significant errors. The very back portion of these panels is meant to be curved, but I totally overlooked that. In my defense, it's relatively simple to overlook. But when it comes to fastening the bed cover/tailgate part, that curve is crucial. I had to attempt to add that curve once the body sides were already attached to the model because I didn't realize it until then. They become somewhat janky.

I was solely responsible for my second error in this area. As you can see, I decided to put together everybody's subassembly before affixing it to the model. It isn't always a negative thing. The terrible part was that they were attached to the model in the correct assembly order. I, therefore, installed the sides first, then the hood, then the bed cover/tailgate, and finally the top of the cab. And you know what? Because of the rails on the bed cover/tailgate area, you are unable to attach the cab top last. Believe me. I made a sincere effort. In the end, it was necessary to take off the bed cover partially, connect the cab top, and then put the bed cover back on.

That concludes my account of how I messed up a lot on this model. With the exception of the curves on the side body panels, it came out nicely—the undercarriage error, of course. Although I don't feel like correcting it right now, I might come back and do it later. I might even write a "case-study" post about mending it. But it has done enough as of right now.